In the past, the high cost of laser technology meant it was accessible only to large-scale factories. However, with technological advancements, the price of lasers has significantly decreased, making them more accessible across the manufacturing industry. Today, even small and mid-sized production facilities can integrate laser solutions into their operations.

What truly sets laser technology apart is its remarkable precision and adaptability. Whether it’s being used in additive manufacturing or detailed laser engraving, this powerful tool has revolutionized various aspects of industrial production.

Before we dive into the top three benefits laser technology can bring to your manufacturing business, let’s first explore some of the common challenges manufacturers face today.

Challenges in Conventional Manufacturing Methods

Traditional manufacturing methods often present several obstacles that can hinder productivity and compromise product quality.

Common issues faced in conventional manufacturing include:

- Limited Precision: Mechanical tools used in traditional setups often lack the accuracy needed for complex or intricate tasks, making it difficult to meet tight tolerances.

- Safety and Efficiency Concerns: Outdated tools and machinery may pose safety hazards for workers and contribute to slower production speeds and reduced efficiency.

- Higher Error Rates: Traditional processes are more prone to inconsistencies and errors, which can lead to defective products. This not only wastes materials and resources but can also raise concerns related to quality control and regulatory compliance.

How Laser Technology Enhances Manufacturing Operations

Industrial laser systems empower manufacturers to produce with exceptional precision and speed. From cutting and welding to marking and engraving, lasers offer a flexible solution for a wide range of manufacturing applications.

Let’s take a closer look at three key ways laser technology helps overcome the limitations of traditional manufacturing methods:

Unmatched Precision and Accuracy

One of the most significant advantages of laser technology in manufacturing is its ability to deliver exceptional precision. By utilizing highly focused beams of light, lasers can perform intricate and detailed tasks with microscopic accuracy.

Laser beams can be narrowed to a fraction of a millimeter, making them ideal for high-precision applications like laser marking. The results are clean, sharp, and consistent—laser cuts produce smooth edges without distortion or burrs. This eliminates the need for post-processing or additional finishing, streamlining production and improving overall product quality.

Improved Quality Control and Traceability

Laser marking technology plays a crucial role in enhancing quality control within manufacturing operations. It allows for the creation of permanent, highly legible marks—such as serial numbers, production dates, and batch codes—that can be used to track products throughout the entire production process.

This traceability ensures every stage of manufacturing meets quality standards and allows for easy identification of any issues. In the case of product defects or recalls, laser markings enable quick and precise batch tracking, making corrective actions faster and more efficient. Best of all, this information is embedded without altering or damaging the product, ensuring both quality and compliance are maintained.

Enhanced Safety in Manufacturing Environments

Safety is a top priority in any manufacturing facility, and laser technology provides a significant boost in this area. Traditional manufacturing methods often involve manual labor or mechanical equipment that can present serious safety risks. In contrast, laser systems automate many complex processes, reducing the need for direct human contact and minimizing the chance of workplace injuries.

Modern laser machines are also designed with built-in safety features. When properly enclosed with interlocked doors and optical density (OD)-rated viewing windows, laser systems can be classified as “Class 1” for safety—meaning they are completely safe for continuous use and pose no risk to unprotected eyes. This makes them a smart, secure choice for today’s manufacturing operations.

Applications of Laser Technology in Manufacturing

Industrial lasers are incredibly versatile and have become essential tools across various sectors within the manufacturing industry. Their adaptability, accuracy, and efficiency make them ideal for a wide range of applications.

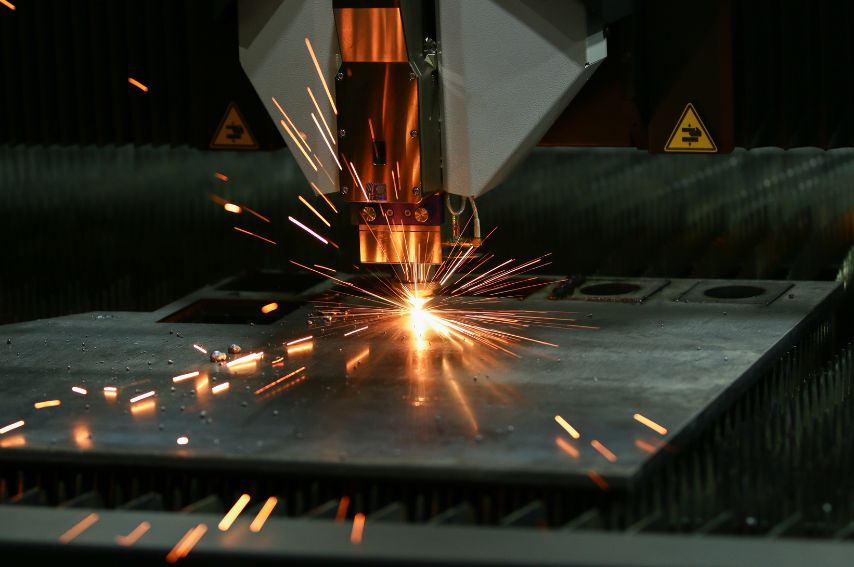

Laser Cutting

Laser cutting is one of the most widely used applications in manufacturing due to its unmatched precision and speed. This technique is ideal for cutting and shaping sheet metal components used in industries like automotive, aerospace, and electronics.

In the medical field, laser cutting is vital for producing highly accurate components such as surgical instruments and stents. Electronic manufacturers also rely on laser cutting for creating and drilling printed circuit boards (PCBs) and other intricate parts.

Additionally, the automotive industry utilizes laser cutting for producing components such as chassis, body panels, gaskets, and interior trim parts. The clean cuts and high level of detail offered by laser systems make them a preferred solution for manufacturers aiming for high-quality, repeatable results.

Laser Engraving

Laser engraving involves using a highly focused laser beam to vaporize the surface of a material, creating permanent marks such as barcodes, serial numbers, text, or decorative patterns. Known for its speed and precision, this method is ideal for high-volume production and fast repetition cycles.

In the medical industry, laser engraving is commonly used to mark surgical instruments, implants, and devices with unique identifiers, usage instructions, and compliance information. These permanent engravings help ensure traceability and meet stringent regulatory standards.

Laser engraving is also widely used in the automotive, aerospace, and electronics sectors to engrave durable marks on metals like stainless steel, aluminum, titanium, and brass. Whether for identification or aesthetic purposes, this technique offers long-lasting results without compromising material integrity.

Laser Processing

Laser processing is playing a transformative role in the battery and electric vehicle (EV) industries by enhancing strength, performance, and production efficiency. One of its key applications is in wire bonding, a technique used to connect electrical components within battery cells and EV systems.

Traditional bonding methods—such as ultrasonic and thermosonic bonding—often lead to weaker, inconsistent connections that can impact overall product reliability. Laser processing offers a superior alternative by creating stronger, more uniform bonds, even with the same materials.

This results in improved conductivity, longer product lifespans, and greater energy efficiency—critical factors for high-performance EV and battery systems. As the demand for electric vehicles continues to grow, laser processing stands out as a crucial technology driving innovation in the sector.

Laser Welding

Laser welding is a powerful and precise technique capable of joining a wide variety of materials, including metals and certain plastics. It delivers cleaner, stronger welds than traditional welding methods, making it ideal for applications where strength, durability, and minimal distortion are essential.

This technology is widely used in industries such as oil and gas, construction, and shipbuilding for the fabrication and repair of pipelines, pressure vessels, and large structural components. In the aerospace and defense sectors, laser welding is critical for assembling high-performance parts like aircraft fuselages, engine components, and missile systems.

Thanks to its ability to produce high-strength, lightweight welds with minimal heat input and deformation, laser welding enhances both the structural integrity and efficiency of final products—key factors in demanding, performance-driven industries.

Laser Texturing

Laser texturing—also known as laser surface texturing or laser surface patterning—is a precise and efficient method used to create detailed textures on various surfaces, enhancing both function and aesthetics across multiple manufacturing sectors.

This technique is widely applied in the production of moulds and dies used in injection molding, extrusion, and casting. By adding micro-textures directly to tool surfaces, manufacturers can improve product quality, reduce wear, and streamline finishing processes.

In the automotive industry, laser texturing is commonly used on interior and exterior components such as trim panels, dashboards, and body surfaces, offering a premium look and tactile feel.

Laser texturing also finds applications in the aerospace sector, where it’s used on parts like turbine blades, airfoils, and structural elements. The textured surfaces can improve airflow, reduce drag, and enhance overall fuel efficiency—contributing to better performance and sustainability.

Laser Marking

Laser marking is a widely used application in industrial manufacturing, offering a reliable and permanent solution for part identification and product traceability. This technology supports various laser types—including fiber, CO₂, hybrid, and UV laser markers—making it suitable for a broad range of materials and industries.

For instance, UV laser markers are commonly used in the medical device industry to mark surgical tools, implants, and diagnostic equipment with critical information such as serial numbers, barcodes, and regulatory data. These marks are highly precise, durable, and biocompatible—ideal for meeting strict healthcare standards.

Laser marking is also essential in general manufacturing for applying batch codes, part numbers, manufacturing dates, and other traceability details on components and assemblies. It ensures consistent quality control, improves logistics, and simplifies recall management—without compromising the structural integrity of the product.

Transform Your Manufacturing Operations with Laser Technology

Laser technology has become an essential part of modern manufacturing, offering unmatched precision, efficiency, and customization capabilities. As this technology continues to advance, its impact on production processes is only growing stronger.

Today, manufacturers across a wide range of industries are embracing industrial lasers to improve product quality, streamline operations, and stay competitive in an increasingly demanding market. From prototyping to high-volume production, laser systems are revolutionizing the way goods are made—delivering consistent, high-performance results.

Ready to improve your manufacturing operations? Contact us today.